Nanomaterials – consulting, analysis and assessment

Thanks to extensive experience in the field of nanoanalysis, we advise customers in the cosmetics, textile, electrical, pharmaceutical and chemical industries. We focus on nanoanalytical investigations, safe handling of nanomaterials in production and on all legal issues.

In addition, we characterise nanomaterials by precise analysis and determine whether a material, a raw material for example, is present as a nanomaterial.

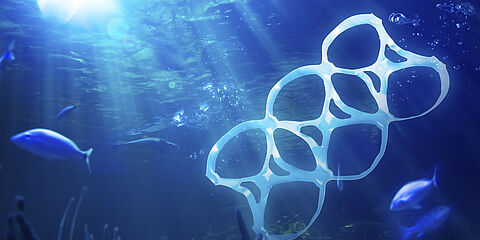

Nanomaterials are playing an increasingly important role in industry,due to the fact that they give products new properties that are not possible with the same materials when their particle size is of a higher order of magnitude. Health and environmental protection, and hence the safe handling of nanomaterials, are also becoming increasingly important. Manufacturers, the processing industry and users of nanomaterials have a responsibility to ensure a high safety standard for consumers and employees.

Thanks to extensive experience in the field of nanoanalysis, WESSLING experts can provide you with competent advice and support with a wide range of services. The focus is on highly qualified consulting and analysis services specifically geared towards your individual requirements.

Our services in detail

Our services in detail

Nanomaterials in cosmetics

Nanomaterials in cosmetics

Legislation has laid down specific requirements for nanomaterials in the EU Cosmetics Regulation. Special assessment and notification requirements apply to cosmetic products with intentionally added, insoluble nanoscale constituents. We will help you meet these requirements with advice and analysis in our laboratories.

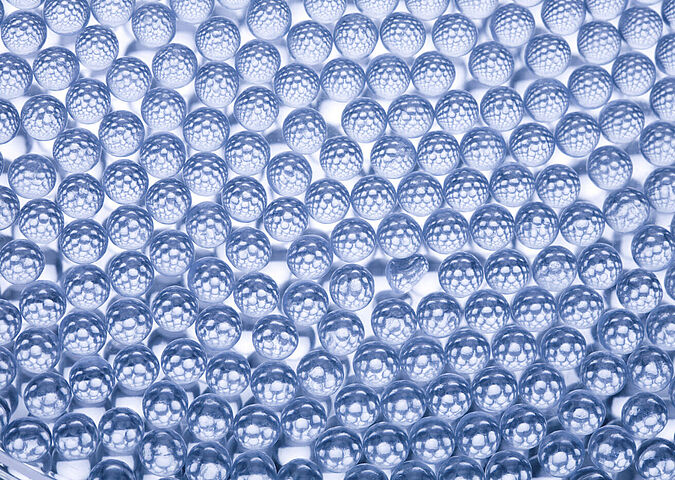

Micelle analysis for cosmetics and pharmaceutical products

The use of active ingredient delivery systems in cosmetics and pharmaceutical products is growing in importance, particularly in skincare products. The active ingredient systems consist of biodegradable, readily soluble nanostructures. These include micelles, liposomes, nanoemulsions and lipid nanoparticles, which have a high cleaning effect.

Our highly qualified consulting service is tailored to your requirements. The analysis of micelles is an interdisciplinary topic shared by nanotechnology experts and cosmetics and pharmaceutical experts. We test how high the concentration of a raw material must be to form micelles and determine their number in the final product.

Our services in the field of micelle analysis:

- Quality analysis of raw materials at a nanoscale and a micron scale

- Comprehensive advice on the provisions of EU Cosmetics Regulation (EC) No. 1223/2009 relating to the nanomaterials used

- Independent assessment and evaluation of your product with regard to the potential incorporation of nanomaterials

- Determination of the critical micelle concentration (CMC concentration)

- Analysis of emulsions containing micelles using cryo-scanning electron microscopy

- Analysis of size distribution and homogeneity using dynamic and static light scattering

- Determination of the critical micelle concentration (CMC)

Further information on our services in the cosmetic field.

Our services in detail

REACH

REACH Regulation: Clear rules for nanomaterials

Since the REACH Regulation (European Chemical Regulation) was developed and drafted, there have been clear rules for nanomaterials along the entire supply chain. In future, manufacturers, importers and users must submit detailed data on nanomaterials and their nanoforms when they are registered with the European Chemicals Agency (ECHA).

Our services within the context of the REACH Regulation

- Advice on product registration with the European Chemicals Agency (ECHA)

- Chemico-physical characterisation of nanomaterials

- Risk assessment of nanomaterials

We are at your disposal for particular questions regarding the analysis of substances in connection with REACH. Read more about our services in the field of chemical safety and REACH here.

Your contact regarding REACH and nanomaterials.

We will be happy to support you.

- David Paris

- +33 06 11 82 70 55

- david.paris@wessling.fr

Our services in detail

Safe handling of nanomaterials

Risk assessment: Safe handling of nanomaterials in the workplace

According to the Occupational Health and Safety Act, it is the duty of every employer to protect their employees from potential hazards. WESSLING experts aid companies of the chemical, cosmetics, food and pharmaceutical industries – both manufacturers and processors of inorganic raw materials and other materials in powder form – in identifying potentially hazardous nanomaterials and carry out a risk assessment in accordance with the current regulations.

Substances and mixtures consisting of manufactured nanomaterials may be hazardous substances, but this is not necessarily the case. The same applies to substances and mixtures that contain manufactured nanomaterials. Risk assessment is the key element of occupational health and safety, on the basis of which, among other things, the necessary health and safety measures are derived and implemented. Appropriate, documented protection from the above-mentioned substances and mixtures is therefore ensured.

Your contact for safe handling of nanomaterials in the workplace

We will be happy to support you.

- David Paris

- +33 06 11 82 70 55

- david.paris@wessling.fr

Our services for your industry

WESSLING provides individual service packages that are tailored to the needs of your company.

WESSLING expertise for nanoanalytical investigations

The characterisation of nanomaterials requires a combination of different analysis techniques that depend on the particular question under consideration. Parameters such a size, form and structure as well as size-dependent photonic properties and chemical composition play a big role in quality assurance.

Characterisation of nanomaterials

The investigation of nanomaterials in different matrices, for example cosmetics, is very demanding. Based on our excellent network with universities and institutes, we are also able to solve complex and challenging problems. Nanomaterials can be present in the form of particles or fibres. At least one dimension is smaller than 100 nanometres. By way of comparison: the ratio between a nanoparticle and a football is about the same as that between a football and the Earth.

Our specific nanoanalysis techniques

- Scanning electron microscopy (FE-SEM/EDX)

- Transmission electron microscopy (TEM/EDX)

- Dynamic light scattering (DLS)

- Laser diffraction (static light scattering) according to ISO 13320-1

- Nanoparticle sizer (SMPS) (measurement of airborne particles)

Our services

- Material and particle analysis: physical and chemical characterisation on a micro- and nanometre scale

- Chemical safety: Consulting on nanomaterials with regard to REACH

- Support in the assessment of nanomaterials according to the legal requirements applicable to, for example, cosmetic products and foodstuffs

- Advice on health and safety in the workplace according to BekGS 527 – manufactured nanomaterials (workplace measurements, dusting tendency)

- Monitoring of indoor air quality, including ultrafine particles (UFP)

- Project-based development of new methods for the identification of nanomaterials in the environment (waste water, surface water, fine dust, UFP)

- Ecotoxicological analysis according to ISO standards and OECD guidelines

Your contact regarding nanoanalysis

We will be happy to support you.

- David Paris

- +33 06 11 82 70 55

- david.paris@wessling.fr