Biogas: cogenerate, inject and liquefy

WESSLING is your partner for all questions relating to biogas. Our analytical expertise makes it simpler to add value to your biogas.

Our experts are continually working to improve biogas yield while maintaining respect for the environment. With our wide range of services, we can support you throughout the production process by analysing your raw and purified biogas.

Our range of services in the field of biogas in detail

Our range of services in the field of biogas in detail

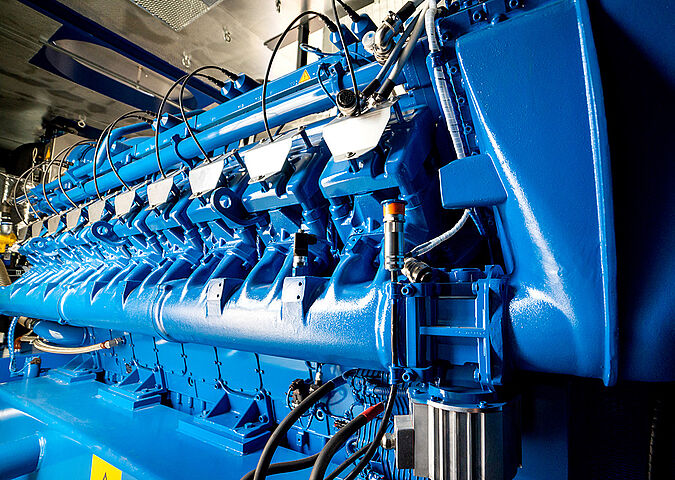

Cogeneration and gas engines

Cogeneration and gas engines

What we call ‘cogeneration’ is the production of heat and electricity from raw or clean biogas.

What components can harm your engine and your installation?

We should mention in particular:

- sulphur (H2S)

- siloxanes (silica)

- ammonia (NH3)

- volatile organic compounds (VOCs)

- ...

These components can cause fouling, deposits and/or acid formation in fuel lines and engines.

The concentrations of harmful pollutants can be determined by on-site tests, but care needs to be taken because not all pollutants are measurable in situ. Certain analyses must be performed in the laboratory.

WESSLING can help you carry out both on-site and laboratory tests.

Do not hesitate to contact us!

Our range of services in the field of biogas in detail

Injection of biomethane into the grid

Injection of biomethane into the grid

Biomethane is injected into the grid through gas companies that permit access to biomethane (purified biogas) on the common network (transmission and distribution systems). Biomethane is subject to strict testing to ensure that it does not affect the quality of the gas and the grid and to protect the safety of users.

Our range of services in the field of biogas in detail

Regulatory checks

Regulatory checks and optimisation of performance

In addition to the tests imposed by the CRE (French Energy Regulation Commission), characterisation of the gas allows the overall performance of the installation to be optimised.

How biogas mapping works

We activate on-site analytical devices and simultaneously measure the quality of the gas at the rate of one point every 2 minutes.

News

All newsYour contact for the topic of biogas

We will be happy to support you.

- Pauline Castillazuelo

- +33 6 13 51 29 59

- pauline.castillazuelo@wessling.fr