How to reduce the costs of soil remediation?

As part of a decontamination project, a prototype for studying the self-purification capacity of a soil was developed by our R&D department. With a new approach, the “BIOVENTAIR” prototype enables decontamination costs to be reduced. We review some of the details of the project here.

How to reduce the costs of soil remediation? How to improve the efficiency of brownfield management and better understand degradation mechanisms? Perhaps by making use of such self-purifying capacities? And by more precisely mapping the contaminated areas of the site? How to limit the environmental impact during decontamination? These were the fundamental questions asked by WESSLING and its commercial partners specialising in the field of contaminated sites and soils.

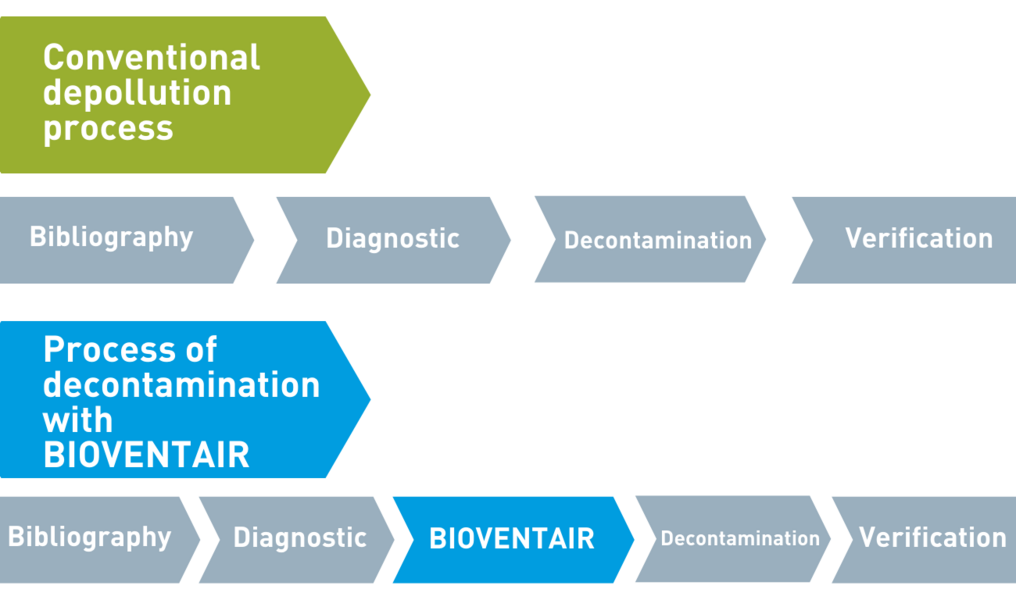

We have developed a new approach and a practical solution to these problems. To do this, our engineers have added a step to the conventional decontamination process:

Between the diagnostic phase and the decontamination phase, we:

- analyse the self-purifying capacity of the soil

and

- map the polluted site in greater detail to limit decontamination to areas that are actually contaminated.

To this end, the R&D department has developed a mobile prototype called BIOVENTAIR. This tool analyses the self-purification capacity of a soil on the site to be decontaminated. Using it reduces transport costs and allows an environmental assessment to be carried out during decontamination.

Your benefits and savings

The use of this prototype allows a more specific biological diagnosis, provides a clear definition of soil capacities and gives a good picture of the stability or volatility of pollutants in the soil. By avoiding unnecessary procedures and selecting the most suitable decontamination techniques, BIOVENTAIR reduces the total cost of decontamination by up to 50%.

Key features of BIOVENTAIR

- To analyse the self-purification capacity of the soil, BIOVENTAIR combines the techniques of venting and targeted microbial simulation

- BIOVENTAIR is effective on organic molecules (THC, BTEX, PCB, etc.)

- The tool is currently being tested on organochlorine matrices and metals

- The analytical version is operational and is currently under further development to scale it up for industrial use.

Download our project as PDF (French)

Your contact :

- Robin T'Jampens

- +33 07 60 73 95 47

- robin.tjampens@wessling.fr

„Would you like to entrust us with thermal or chemical biodegradability tests? Do not hesitate to consult us! We will be able to meet your needs.“